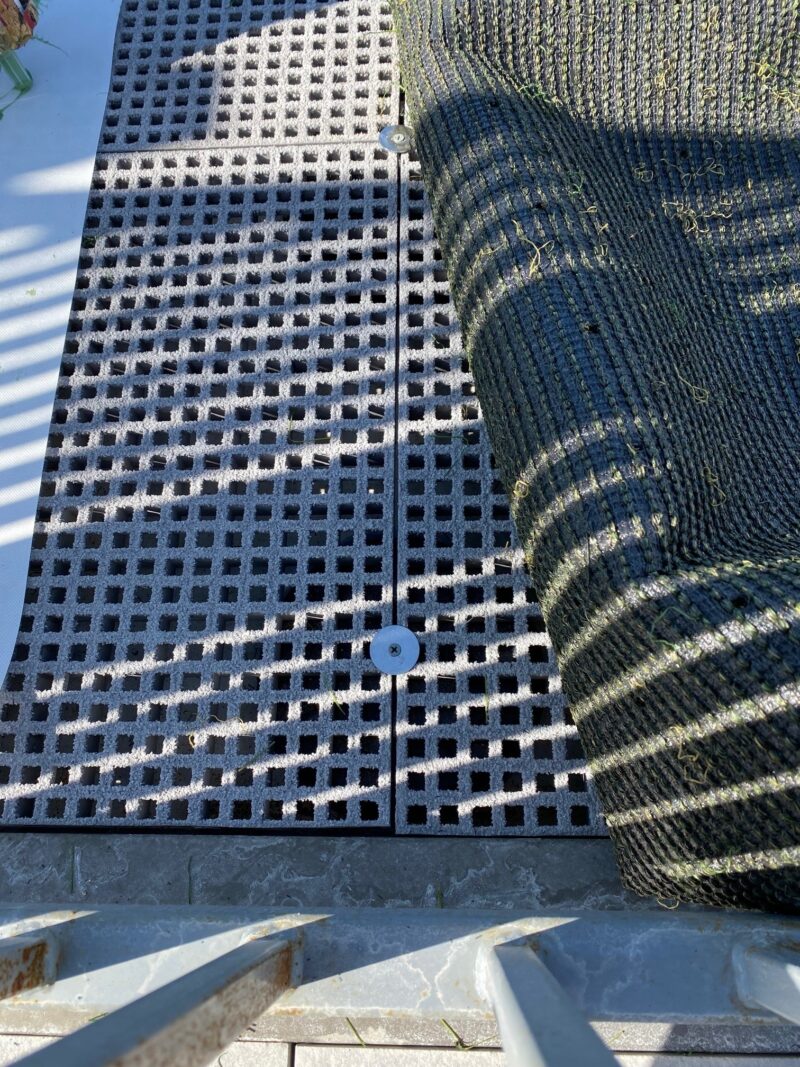

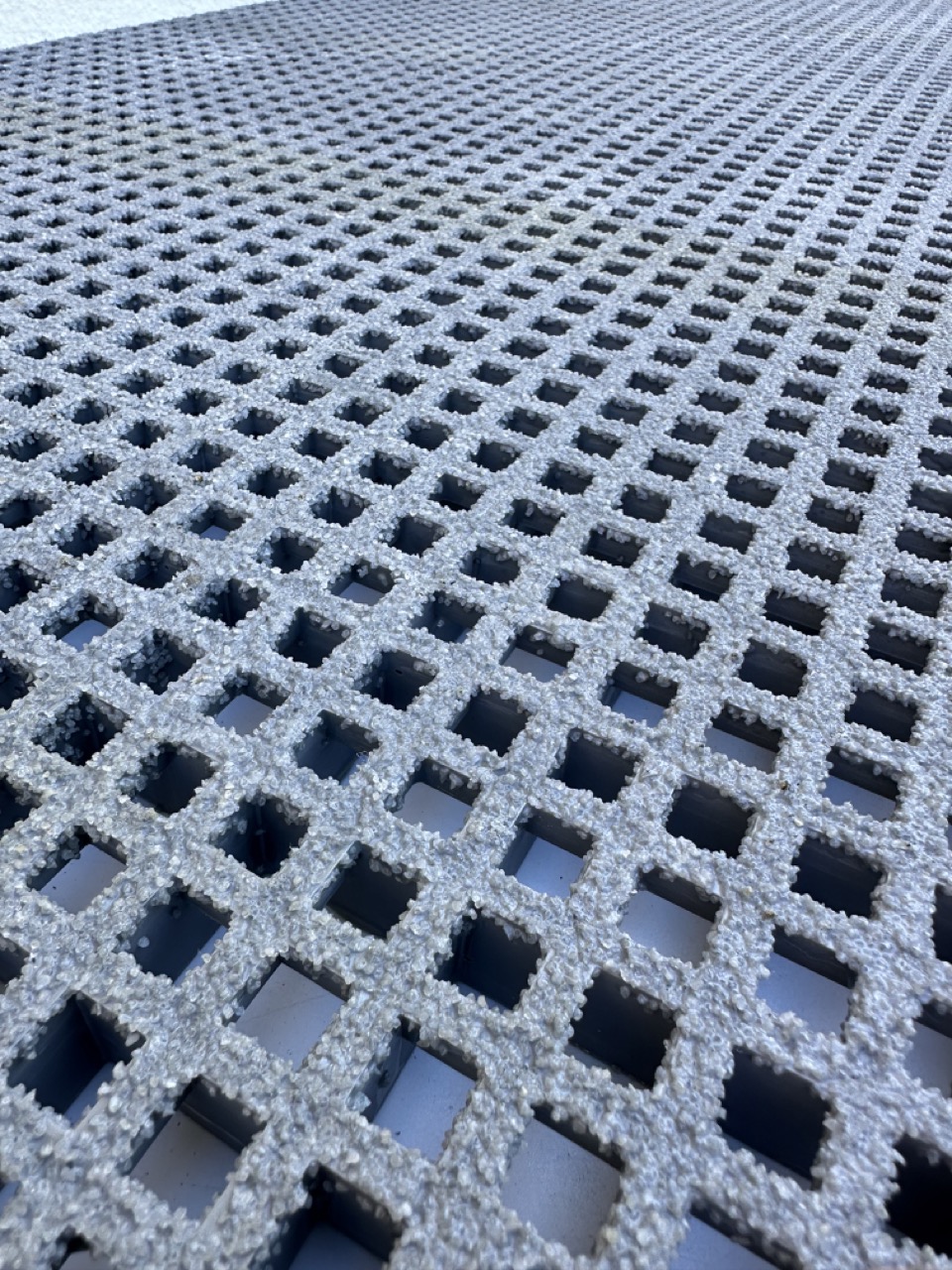

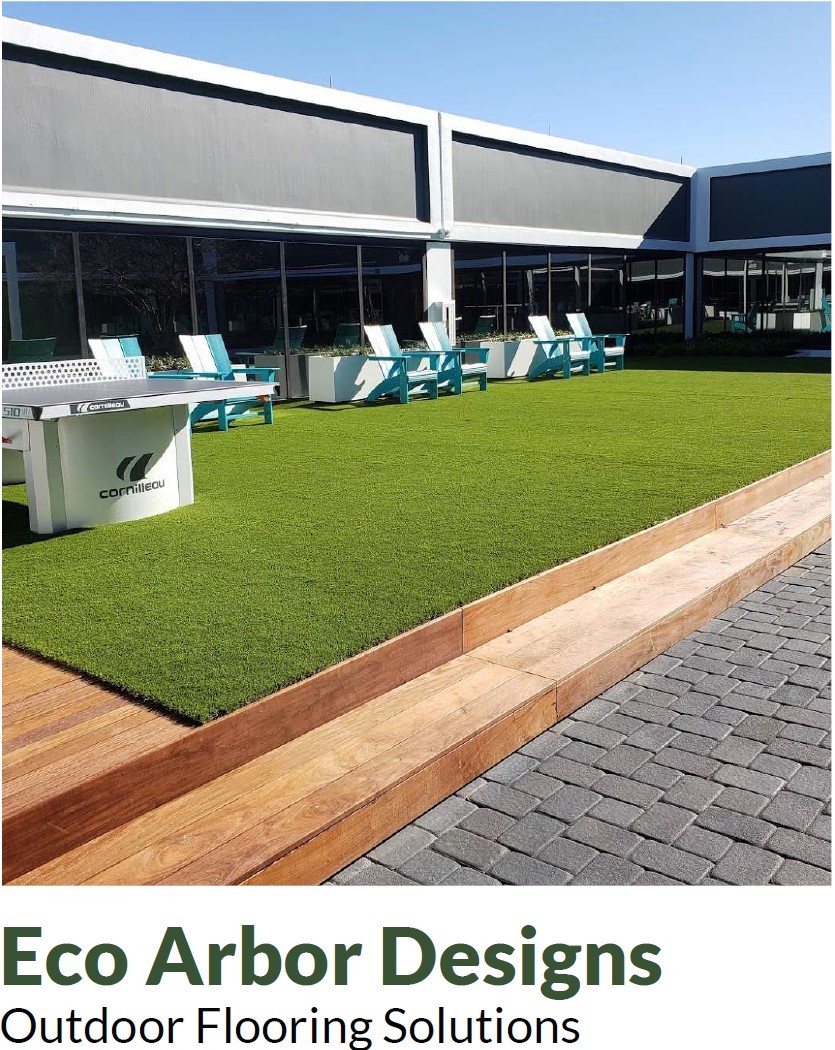

Raise floors featuring artificial turf, rubber flooring or other non weight bearing surfaces require additional substrate support. Our Deck Turf FRP (Fiberglass Reinforced Plastic) panels install over our pedestal system providing a structural floor to lay turf as well as wood deck tiles, porcelain pavers, concrete pavers or any other exterior floor desired. These lightweight grated panels provide unparalleled performance to allow mixed flooring materials to be used seamlessly in any application including pool surrounds, outdoor terraces, rooftop decks, patios, balconies and other exterior areas

Benefits:

• Does not break down, rot, rust, crack or deflect when stepped on

• Create structural support for non structural flooring options (turf, rubber, etc)

• Extends load-bearing capacity for heavy duty commercial flooring applications

• Grated construction allows for drainage

• Easily cut to fit any desired size or shape

• Necessary for created elevated turf floors, a popular green and visually appealing rooftop floor.

For additional information: